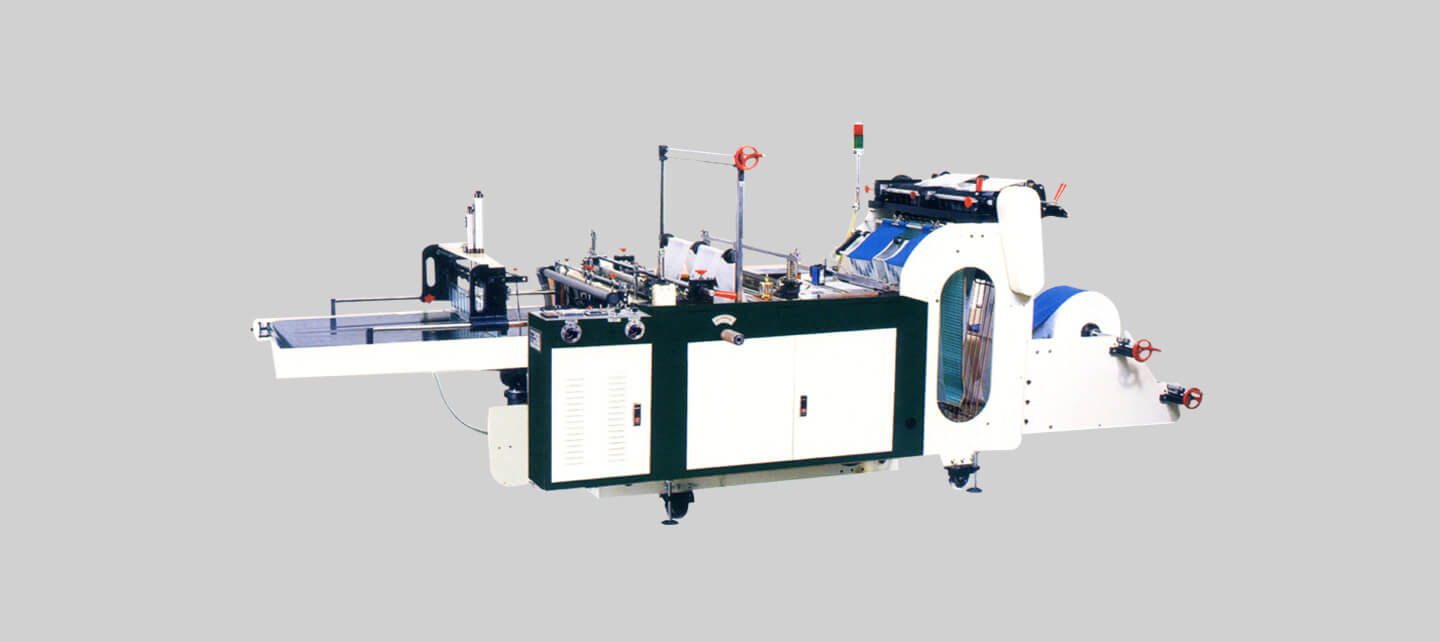

Multi-line bag making machine + heat-slitting system

32BFA-V+SL10

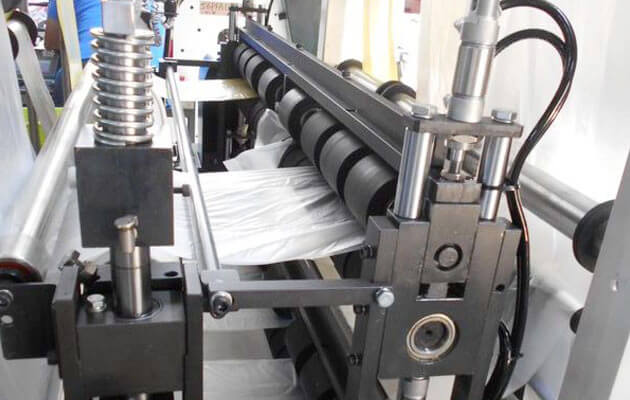

- Cold-cut system - For thin film material. Machine uses upper heating knife and silicon roller base for sealing. Cutting knife before bag outfeeding.

- Fixed type heat-slitting - Multi-line fixed type heat slitter are available depending on the width required from 1" to 4" width narrow bags.

- Synchronized Feeding and cutting speed : Inverter controlled feeding matching main machine speed for easy operation without manual adjustment.

- LCD touch panel : Easily operable human-computer interface to access parameter changes and production monitoring

- Socket type IC circuit control : Automated control system can be easily replaced by socket plugin.

- Sealing pause : Program controlled pauses on lowest point to elongate required sealing time for thick film

- Malfunction alarm / stop : Alarm & auto-stops for abnormal temperature / No material feed / Photocell tracking miss (3 times)

Available Optional Device

Model

Choose the correct model specification

Explore from existing machines and find out endless opportunities