What is Biodegradable material?

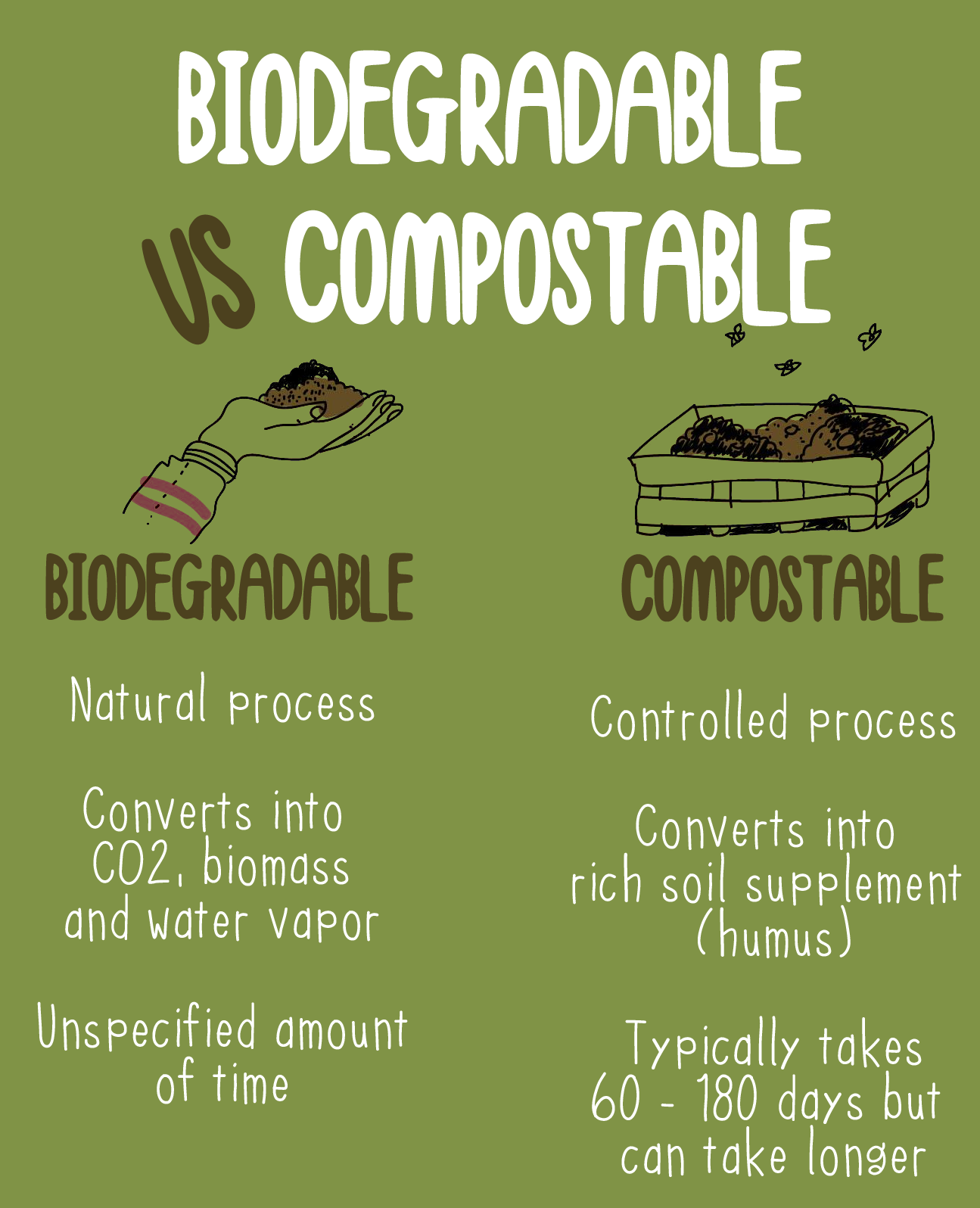

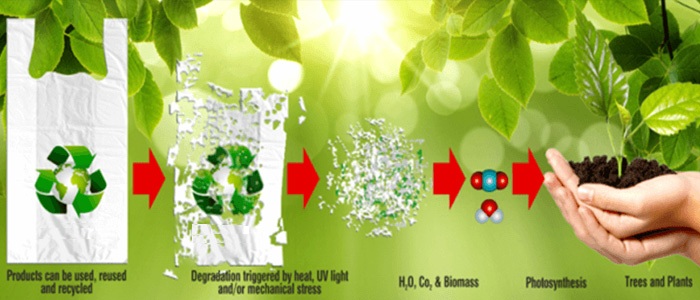

• Biodegradable materials naturally break down and return to nature after disposal.• Microorganisms like bacteria and fungi play a crucial role in the decomposition process.

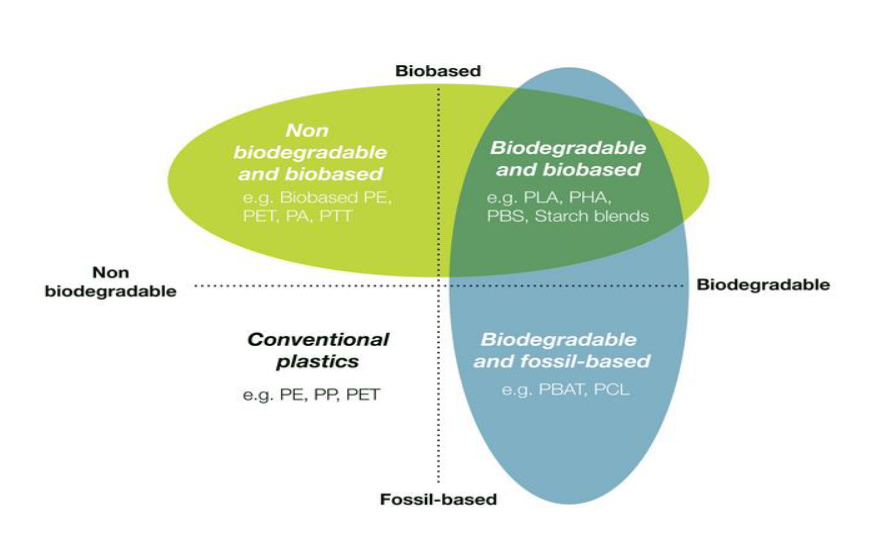

• Types of Biodegradable materials: PLA, PHA, PBS, Starch Blends, PBAT, PCL

What are the Benefits?

1. Safer environment:

Biodegradable materials break down naturally, reducing the accumulation of waste

2. Resource Conservation:

Biodegradable materials are often derived from renewable resources, such as plant-based materials, reducing reliance on finite resources like fossil fuels.

3. Health Benefits:

Biodegradable materials often have a lower likelihood of leaching harmful chemicals into the environment, reducing potential health risks.

4. Consumer Appeal:

With increasing awareness of environmental issues, products made from biodegradable materials have gained popularity among environmentally conscious consumers.

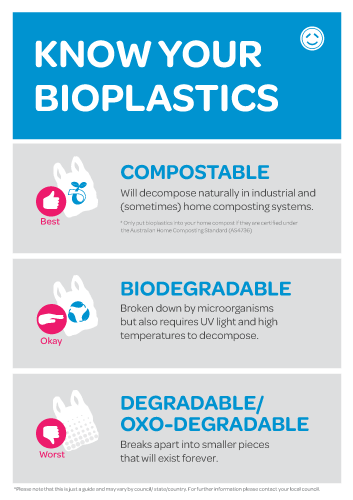

Know Your BIO Plastics

.jpg)

We're thrilled to be on a sustainability journey alongside our Indian partner, ECOLASTIC (LINK)!

ECOLASTIC, a renowned packaging supplier, excels in providing various solutions with their expertise in bio plastic bags.

Ready to jump on the sustainability bandwagon? PAL is here to lend a hand!

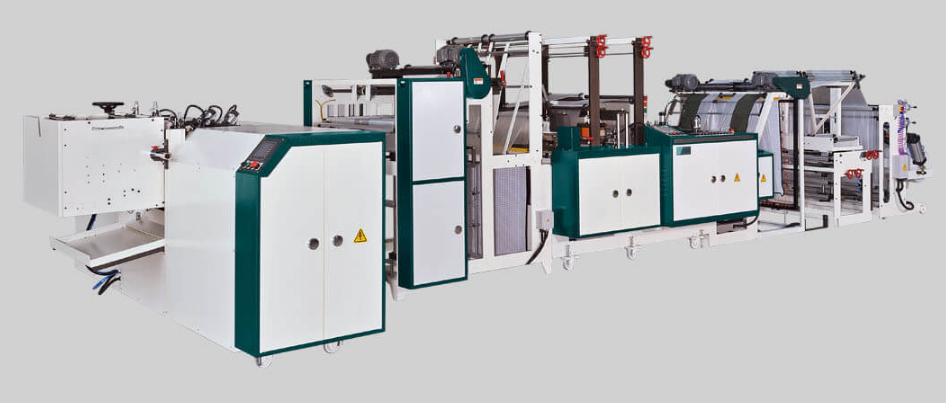

PL42TPFA-V250-2

SERVO MOTOR DRIVE T-SHIRT BAG MAKING MACHINE

WITH DIE CUTTER, HOT CUTTING TYPE

High-speed – Servo Driven production at 250 cycles/min.

For Printed bag – Double servo motors & photocells control 2 lines production for printed bags.

Flexible production – Interchangeable between 2 lines Large bags and 4 lines small bags by simply changing the die cutter and sealing bar.

Easy operation – Easy operation with servo/computer controlled motion for all levels of operators.

Heavy Duty unwinder allows easy change of jumbo rolls for operators, optional EPC & Pressing rollers to stabilize film feeding.

Optional folding devices - Folding device available on demand before collection unit for easy packaging of oversize bags.

Product Page: LINK

Video: LINK

PL32BFWFA-V200H

SERVO MOTOR THICK GAUGE PERFORATED ROLLSTOCK GARBAGE BAG MAKING MACHINEWITH AUTO-REWINDER (CORELESS)

Fully automatic rewinder - Coreless rewinder uses 2 sets of forks for automatic non-stop finished roll change.

High speed hot-cut system:Upper sealing blade & bottom heating wire makes strong and high speed sealing.

Synchronized Feeding and cutting speed:Inverter controlled feeding matching main machine speed.

Product Page: LINK

Video: LINK

Drop us your bag requirement, let us impress you with the perfect solution!