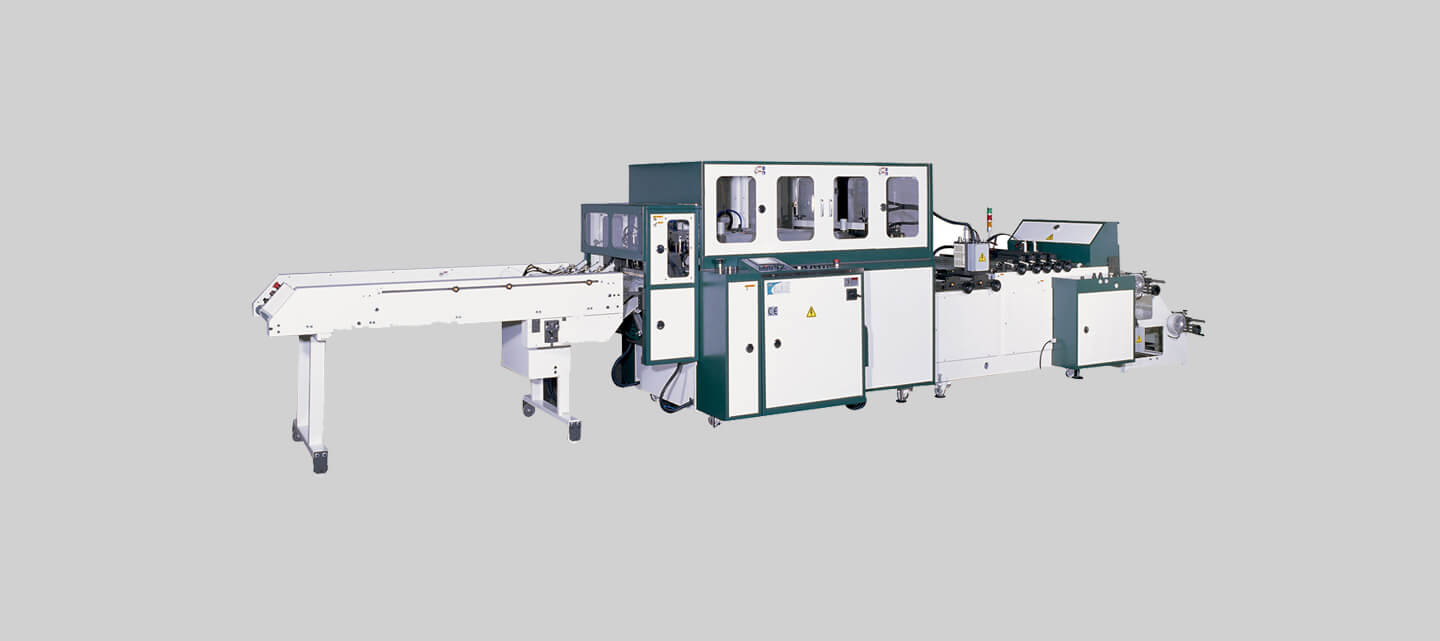

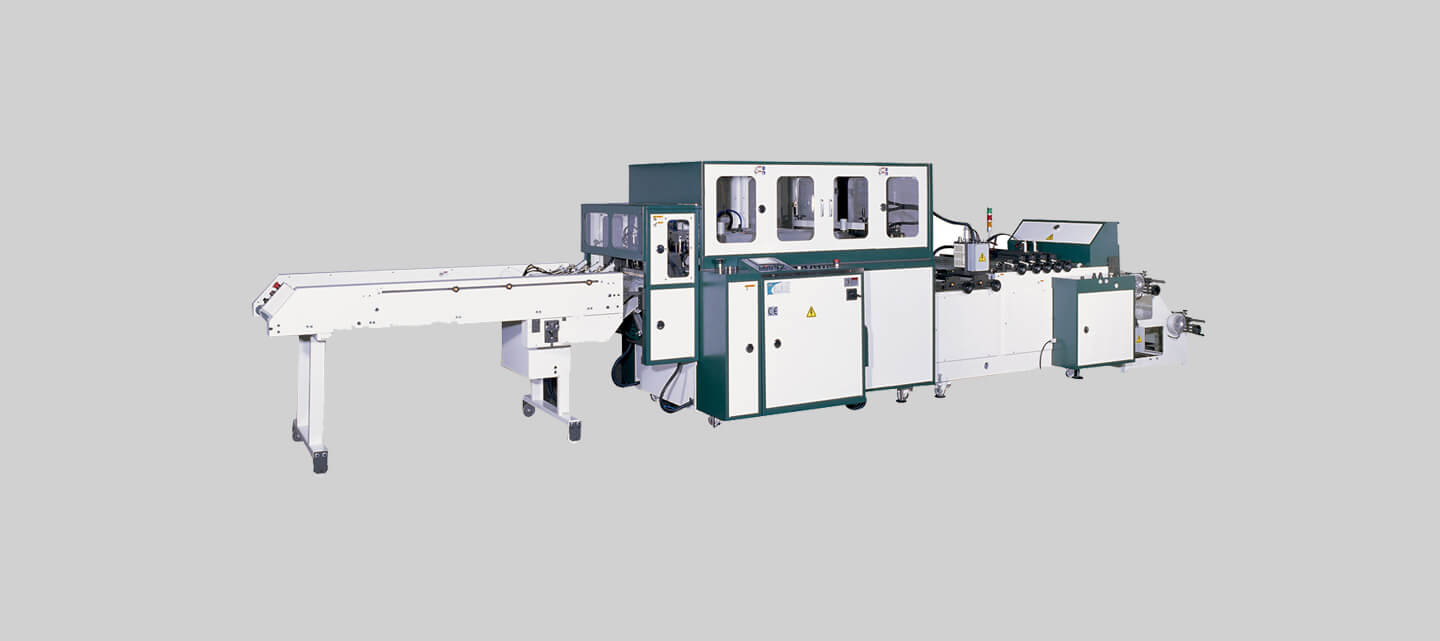

Flower sleeves making machine

SWF-V

-

Synchronized Feeding and cutting speed : Inverter controlled feeding matching main machine speed for easy operation without manual adjustment.

-

German "Sick" photocell registration : Reliable and accurate print registration and positioning

-

LCD touch panel : Easily operable human-computer interface to access parameter changes and production monitoring

-

Socket type IC circuit control : Automated control system can be easily replaced by socket plugin.

-

Malfunction alarm / stop : Alarm & auto-stops for abnormal temperature / No material feed / Photocell tracking miss (3 times)

-

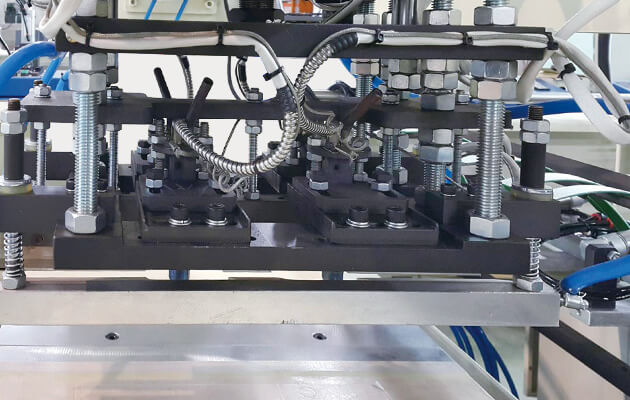

Adjustable slant sealing blades - weld & cut simulatneously against silicon belt. Sealing blade angles and distances are adjustable based on specifications. Cuts 2 bag in 1 stroke.

-

Cold pin blocking - Cold pin blocks finished sleeves, take out by gripper & conveyor or by manual labour.

Available Optional Device

-

Continuous perforation device -

-

Circular perforation blade are fixed and perforated line parallel to material feed direction.

-

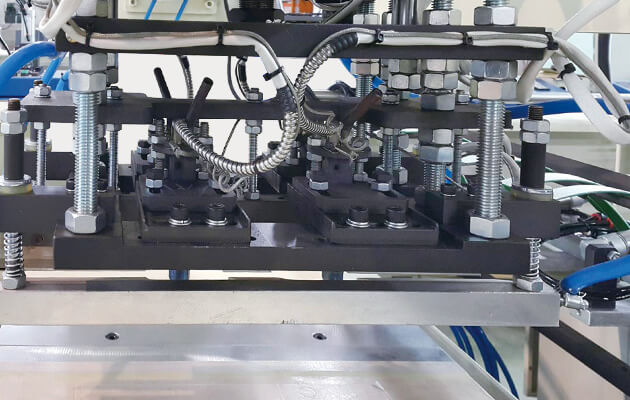

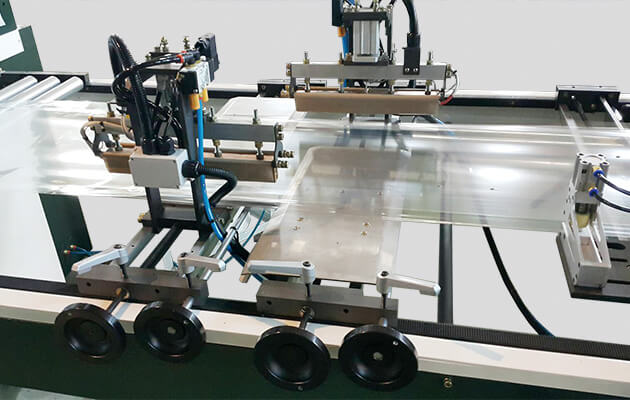

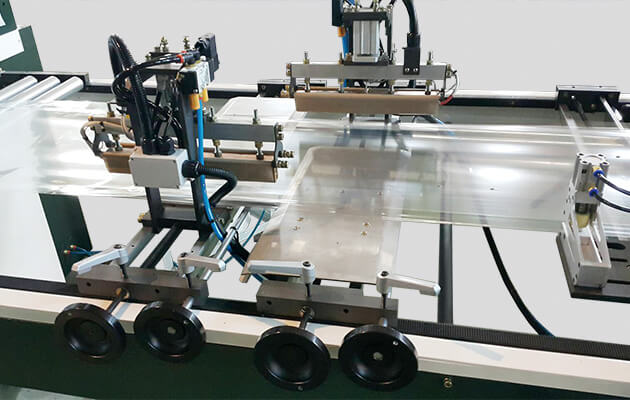

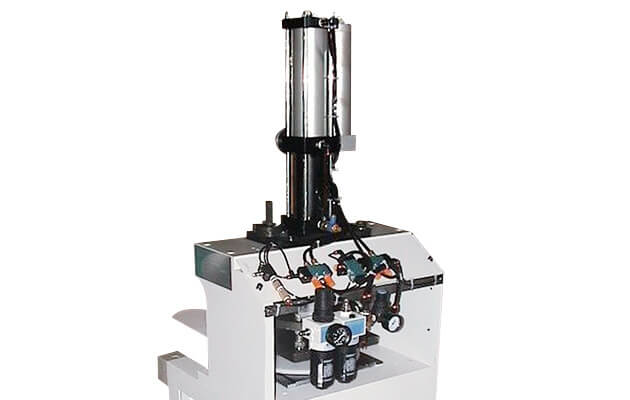

Inline Continuous hole punch (CP1000) -

-

6 points controlled pneumatic punch set can change hole punches position and pattern easily by managing the punch timing seperately for every control point, continuous process.

-

-

-

Saw type punch for punching hole on thick-gauge film

-

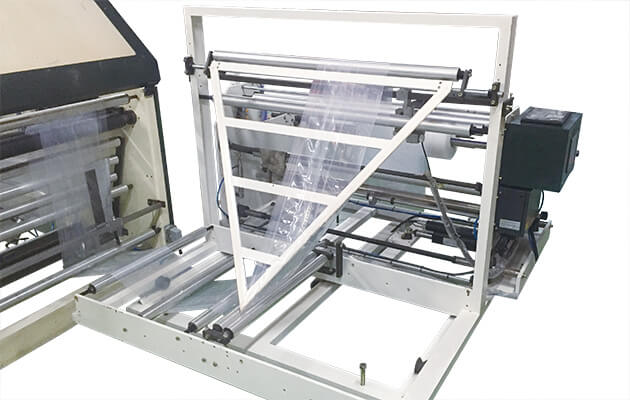

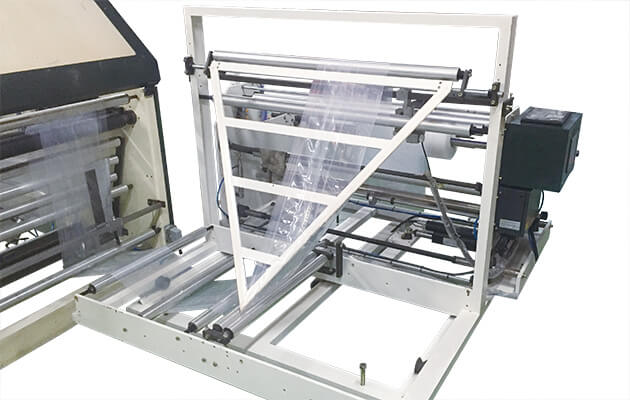

Triangle folding device -

-

Sheet film is folded in half by passing triangular frame and pinch.

-

Hot-cut round Calendar Punch -

-

Heated round punch units with pneumatic punch unit melt finished piles together for calendar type bags. Round holes can be hanged on wall or racks for easy access.

-

Horizontal bottom sealing -

-

Horizontal sealing seals the bottom of the cone shape sleeves, requires 2 stations (1 for each end)

-

Servo driven ultrasonic sealing -

-

Servo-belt drives the ultrasonic unit across to seal special materials such as non-woven & laminated paper. Distance and angle adjustable.

-

Inline softloop insertion -

-

Automatically cut and insertion softloop film handle onto finished bags, requires 2 stations (1 for each end)

-

Twin servo photocell tracking -

-

For registering printing marks on both top and bottom film seperately and position them in the same spot.

-

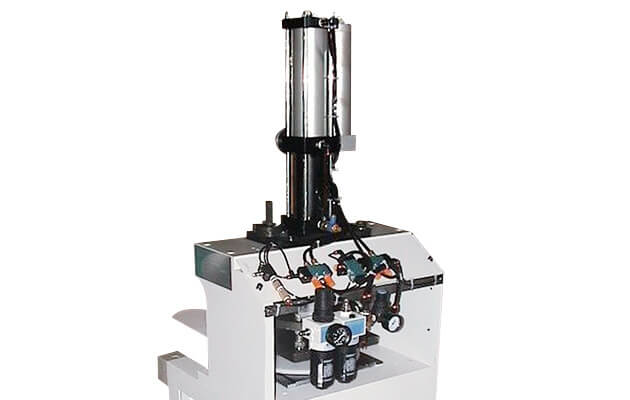

Offline heat needle punch -

-

Heated needle roller perforates film surface for vapor to escape

-

Irregular sealing knife -

-

Customized sealing knife design available based on customer demands

-

Wave top manual punch -

-

Off-line punching the finished sleeves with irregular shapes.

Model

Choose the correct model specification

Explore from existing machines and find out endless opportunities