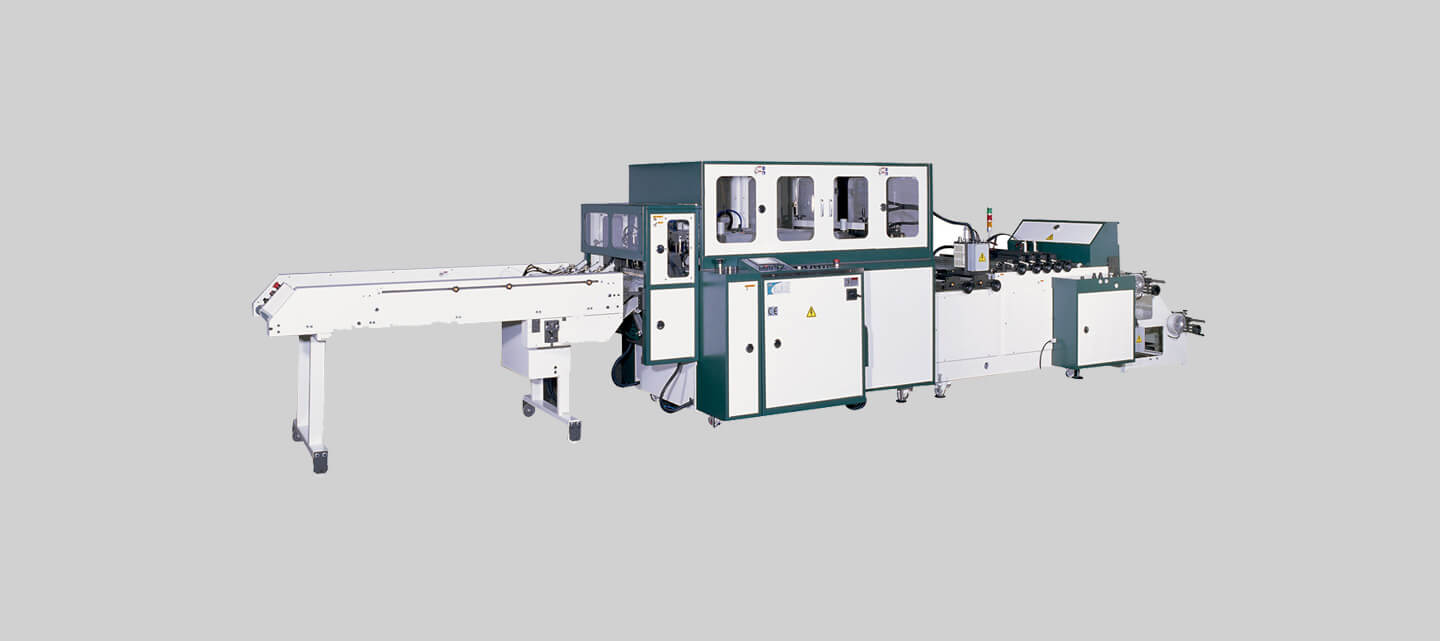

Fully Automatic Flower Sleeves Making Machine

SWFFA-V

Looking for a next-generation Flower Sleeve Bag Making Machine that combines automation, flexibility, and precision? Our Fully Automatic Flower Sleeves Making Machine is engineered for manufacturers who demand uncompromising quality and seamless production performance. Designed to meet the evolving needs of floral packaging, this system offers superior sealing, customization tooling, and efficient stacking—all with minimal operator intervention.

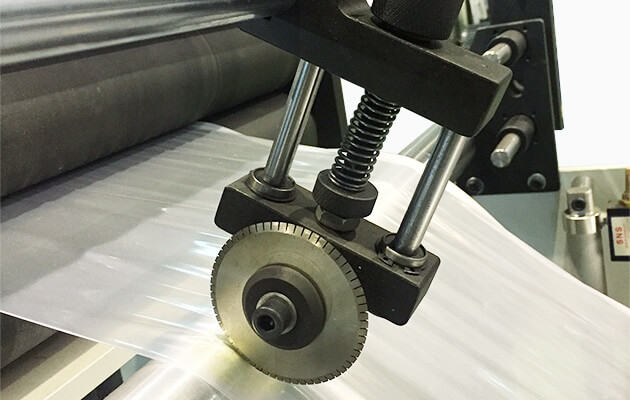

- Synchronized Feeding and cutting speed : Inverter controlled feeding matching main machine speed for easy operation without manual adjustment.

- German "Sick" photocell registration : Reliable and accurate print registration and positioning

- LCD touch panel : Easily operable human-computer interface to access parameter changes and production monitoring

- Socket type IC circuit control : Automated control system can be easily replaced by socket plugin.

- Malfunction alarm / stop : Alarm & auto-stops for abnormal temperature / No material feed / Photocell tracking miss (3 times)

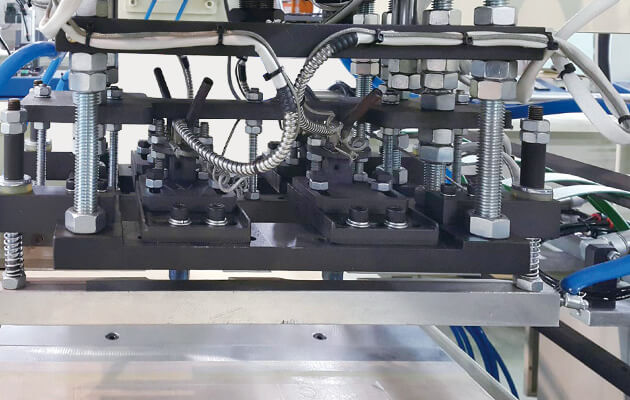

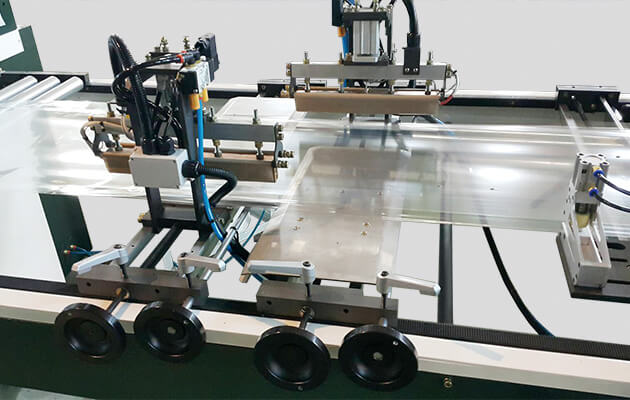

- Adjustable slant sealing blades - weld & cut simulatneously against silicon belt. Sealing blade angles and distances are adjustable based on specifications. Cuts 2 bag in 1 stroke.

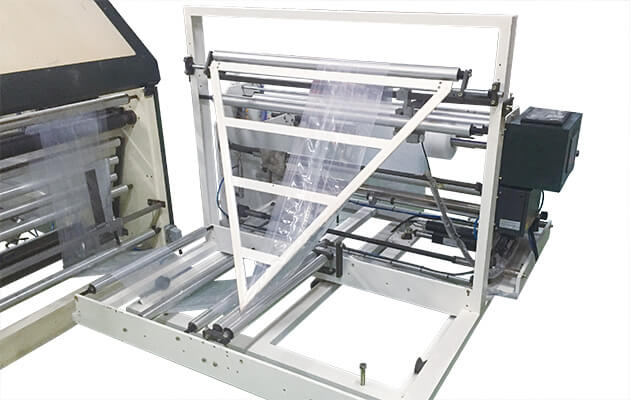

- Cold pin blocking - Cold pin blocks finished sleeves, take out by gripper & conveyor or by manual labour.

- Gripper & conveyor units - blocked piles are removed by gripper and lay on conveyor for labour collection.

Available Optional Device

Model

Choose the correct model specification

Explore from existing machines and find out endless opportunities