Jumbo Tensionless thick gauge bottom seal bag making machine

BF-V (50"+)

- Synchronized Feeding and cutting speed : Inverter controlled feeding matching main machine speed for easy operation without manual adjustment.

- LCD touch panel : Easily operable human-computer interface to access parameter changes and production monitoring

- Socket type IC circuit control : Automated control system can be easily replaced by socket plugin.

- Sealing pause : Program controlled pauses on lowest point to elongate required sealing time for thick film

- Malfunction alarm / stop : Alarm & auto-stops for abnormal temperature / No material feed / Photocell tracking miss (3 times)

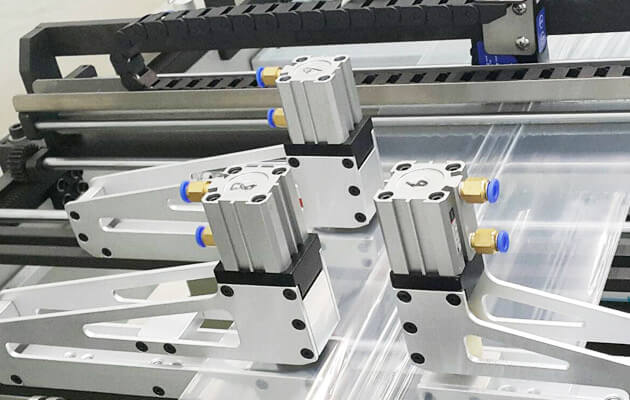

- Tensionless thick gauge hot-cut system - Upper sealing blade & bottom heating wire makes strong and high speed sealing. Tensionless sealing avoids sealing line pull& elongation for highspeed production. Seperated upper and bottom temperature control for easy micro-adjustment.

- Extra large model - For production of bag over 1M & Length over 2M. Setup may varies depends on variety and condition of film & bags.

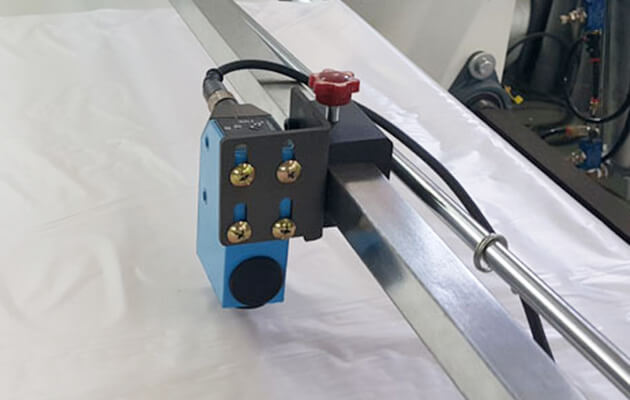

Available Optional Device

Model

Choose the correct model specification

Explore from existing machines and find out endless opportunities