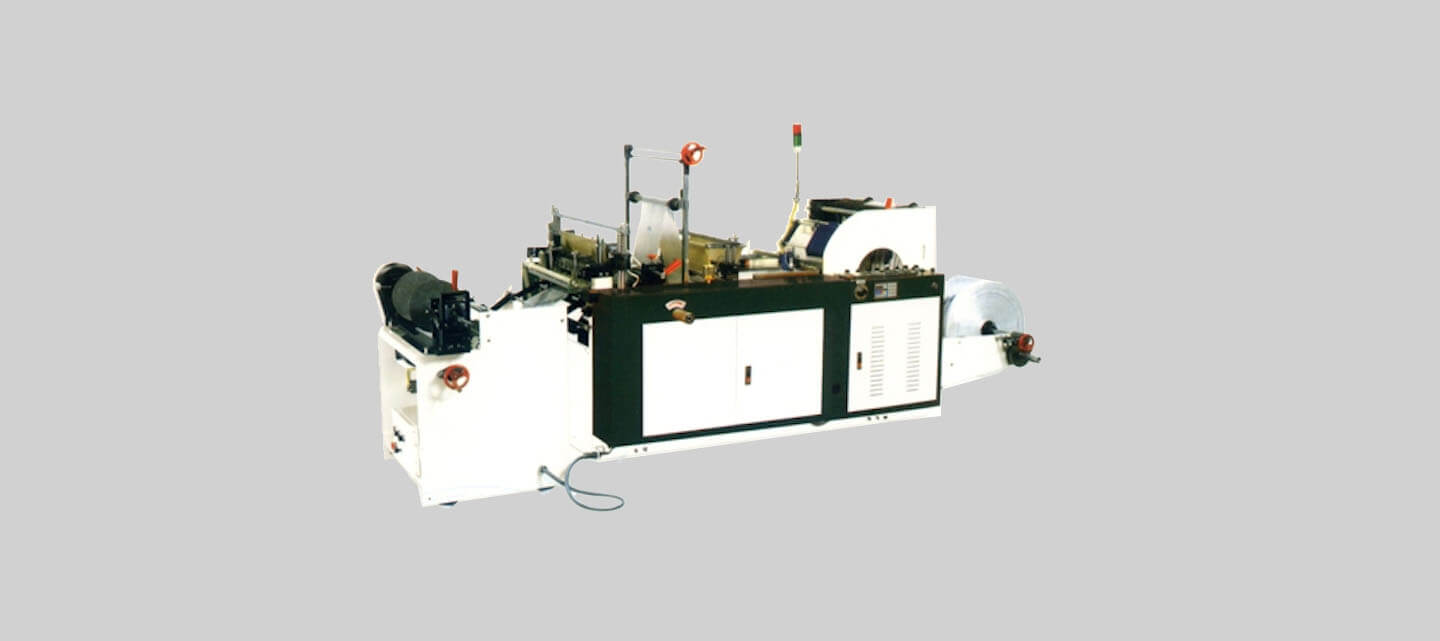

Semi-auto tensionless bag on roll making machine (manual roll change)

BFW-V

- Manual change rewinder - Economy system by manually paper core or coreless rewinder between finished roll and next roll.

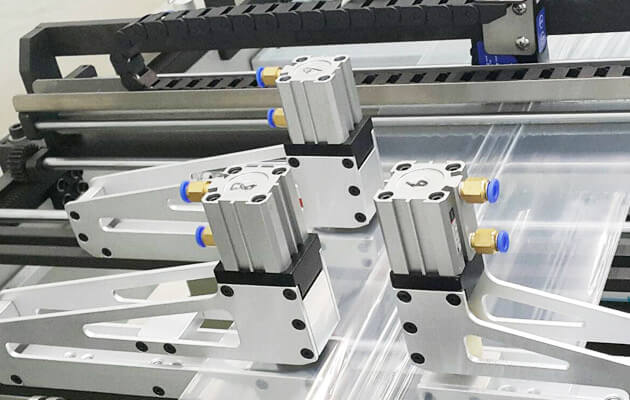

- High speed hot-cut system:Upper sealing blade & bottom heating wire makes strong and high speed sealing. Seperated upper and bottom temperature control for easy micro-adjustment.

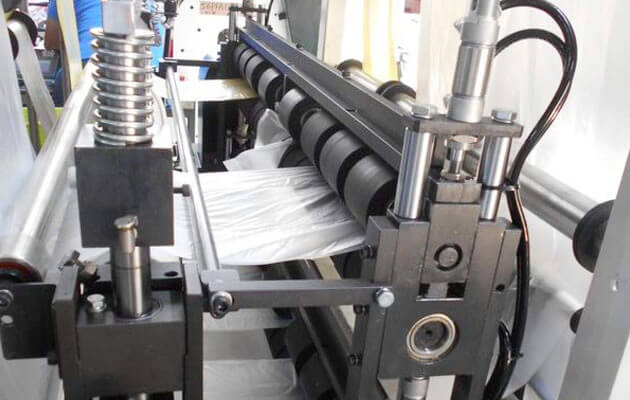

- Synchronized Feeding and cutting speed:Inverter controlled feeding matching main machine speed for easy operation without manual adjustment.

- German "Sick" photocell registration:Reliable and accurate print registration and positioning

- LCD touch panel:Easily operable human-computer interface to access parameter changes and production monitoring

- Socket type IC circuit control:Automated control system can be easily replaced by socket plugin.

- Malfunction alarm / stop:Alarm & auto-stops for abnormal temperature / No material feed / Photocell tracking miss (3 times)

Available Optional Device

Model

Choose the correct model specification

Explore from existing machines and find out endless opportunities