Zipper Film Bag Making Machine

SWZ-V

- Synchronized Feeding and cutting speed : Inverter controlled feeding matching main machine speed for easy operation without manual adjustment.

- German "Sick" photocell registration : Reliable and accurate print registration and positioning

- LCD touch panel : Easily operable human-computer interface to access parameter changes and production monitoring

- Socket type IC circuit control : Automated control system can be easily replaced by socket plugin.

- Malfunction alarm / stop : Alarm & auto-stops for abnormal temperature / No material feed / Photocell tracking miss (3 times)

- Zipper film system - Zipper extruded at the same time of film extrusion. Can be in-lined by extuder - printer - bag making.

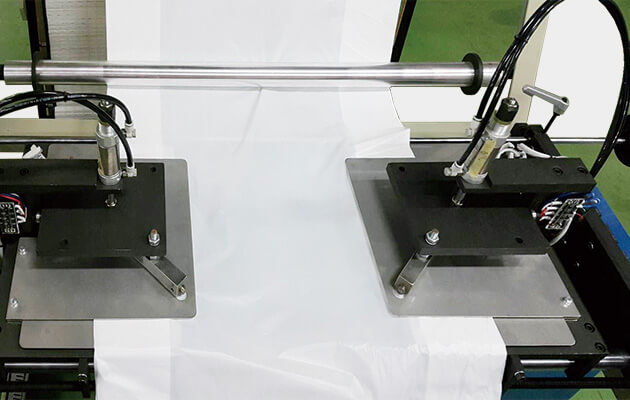

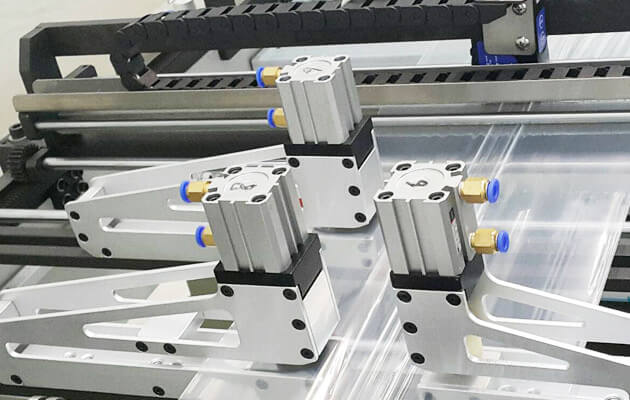

- Zipper sealing system - Side seal units and feeding rollers designed for zipper film production. Cooling pressor cools sealed bag on silicon belt to avoid zipper deforming.

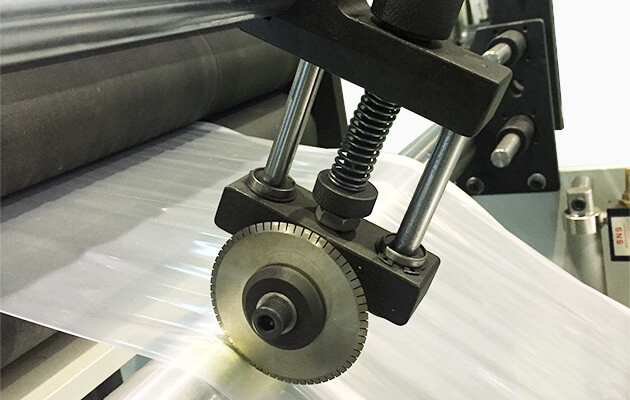

- Double bag system - Small bags are extruded with 2 zippers and cold-slitted on bag making machine.

Available Optional Device

Model

Choose the correct model specification

Explore from existing machines and find out endless opportunities