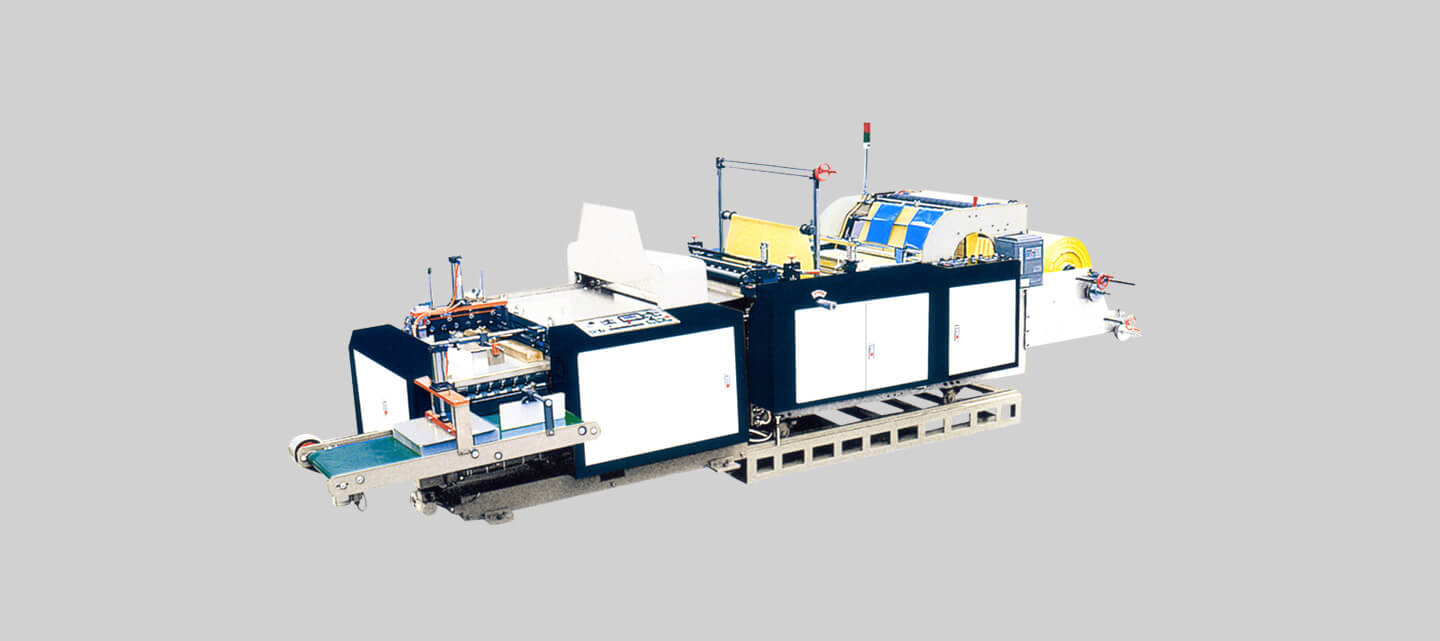

Bottom seal bag making machine + bag folding system

BGFA-V

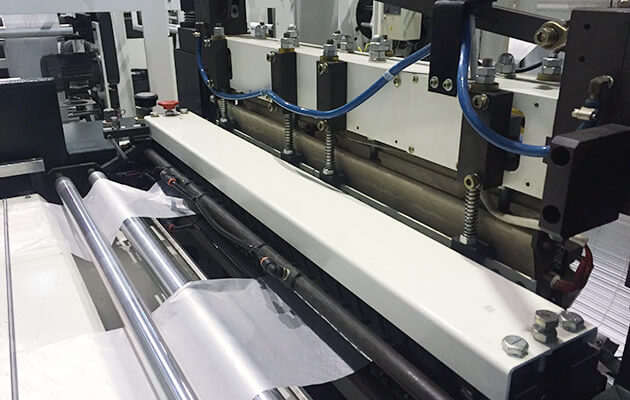

- Tensionless high speed hot-cut system : Upper sealing blade & bottom heating wire makes strong and high speed sealing. Tensionless sealing avoids sealing line pull& elongation for highspeed production. Seperated upper and bottom temperature control for easy micro-adjustment.

- Synchronized Feeding and cutting speed : Inverter controlled feeding matching main machine speed for easy operation without manual adjustment.

- German "Sick" photocell registration : Reliable and accurate print registration and positioning

- LCD touch panel : Easily operable human-computer interface to access parameter changes and production monitoring

- Socket type IC circuit control : Automated control system can be easily replaced by socket plugin.

- Malfunction alarm / stop : Alarm & auto-stops for abnormal temperature / No material feed / Photocell tracking miss (3 times)

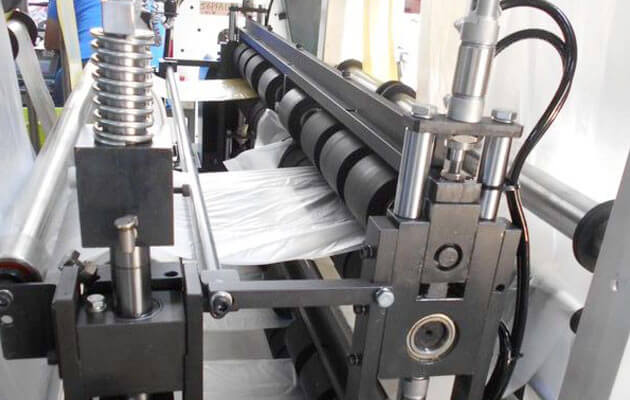

- Automatic Folding system - Servo-controlled 1st & 2nd fold individually (piece by piece), 3rd fold by pneumatic cyllinder every 1-15 pieces pile. 4th & 5th folds by optional.

- Cold-cut system - For thin film material. Machine uses upper heating knife and silicon roller base for sealing. Cutting knife before bag outfeeding.

Available Optional Device

Model

Choose the correct model specification

Explore from existing machines and find out endless opportunities