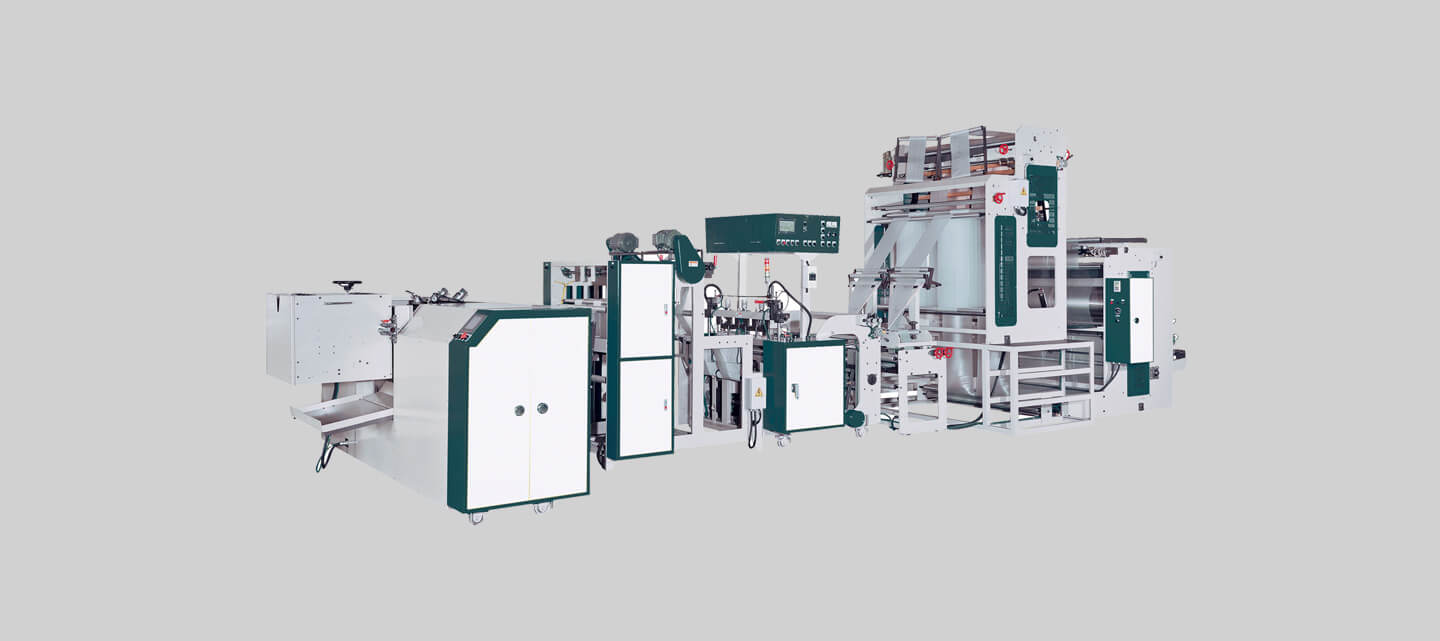

Fully Automatic Bottom Seal Bag On Roll Making Machine + Heat-Slitting & Post-Gusset System

BFWFA-V+SLG

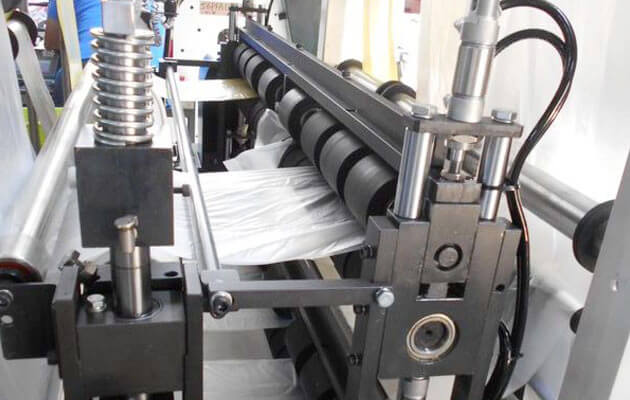

- High speed hot-cut system:Upper sealing blade & bottom heating wire makes strong and high speed sealing. Seperated upper and bottom temperature control for easy micro-adjustment.

- Synchronized Feeding and cutting speed:Inverter controlled feeding matching main machine speed for easy operation without manual adjustment.

- German "Sick" photocell registration:Reliable and accurate print registration and positioning

- LCD touch panel:Easily operable human-computer interface to access parameter changes and production monitoring

- Socket type IC circuit control:Automated control system can be easily replaced by socket plugin.

- Malfunction alarm / stop:Alarm & auto-stops for abnormal temperature / No material feed / Photocell tracking miss (3 times)

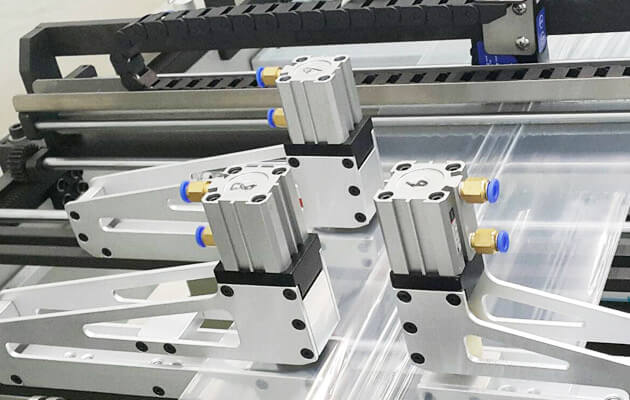

- Heat-slitting + post-gusset system - Adjustable heat-slitting knife slit and seal jumbo bobbin film in to multiple lines. Post-gusset stations makes gussets on slitted film.

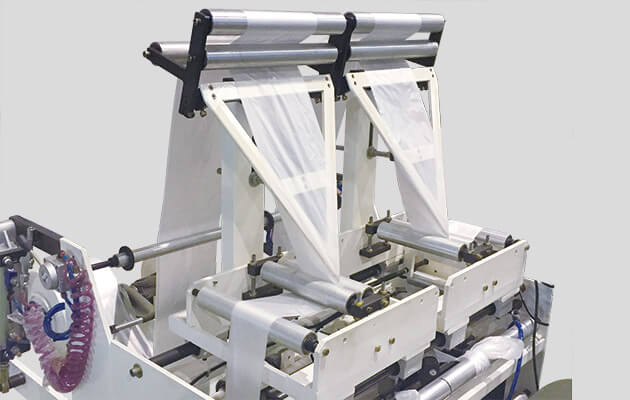

- Fully automatic rewinder - Fully automatic non-stop system inserts paper core & change finished roll. Coreless rewinder uses 2 sets of forks for automatic non-stop finished roll change.

Available Optional Device

Model

Choose the correct model specification

Explore from existing machines and find out endless opportunities