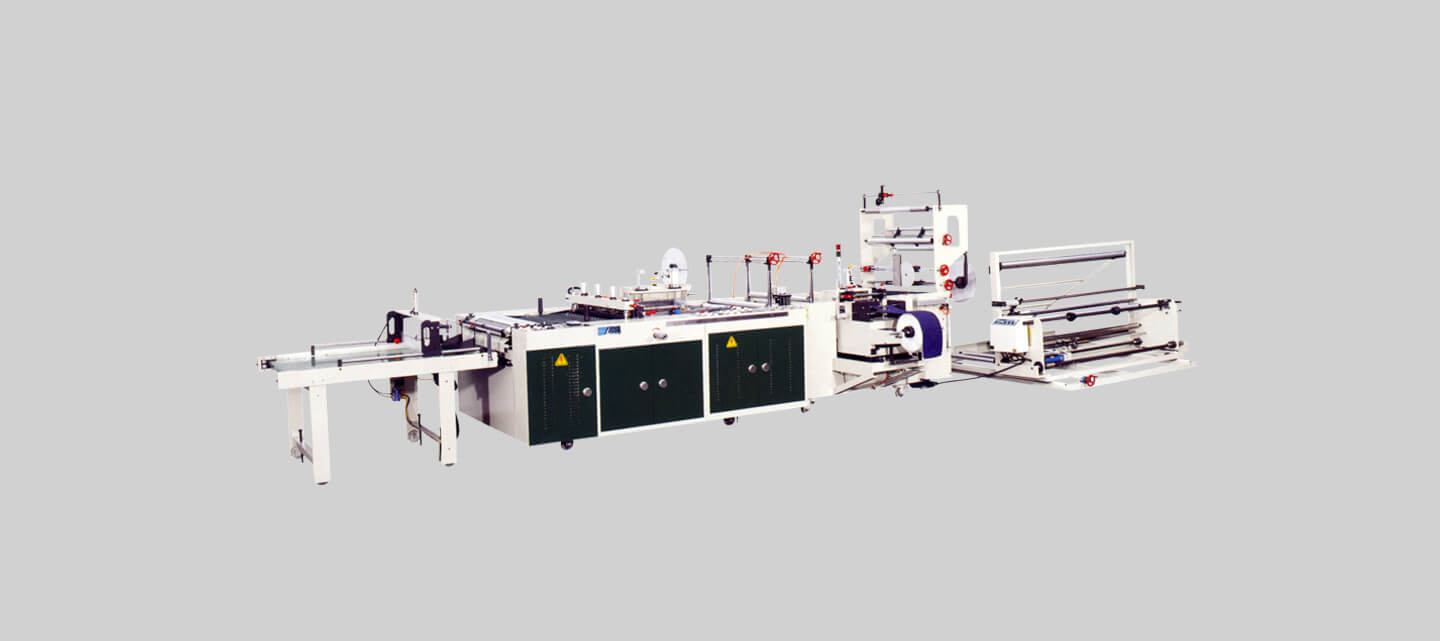

Side seal patch handle shopping bag making machine

PHFA-V

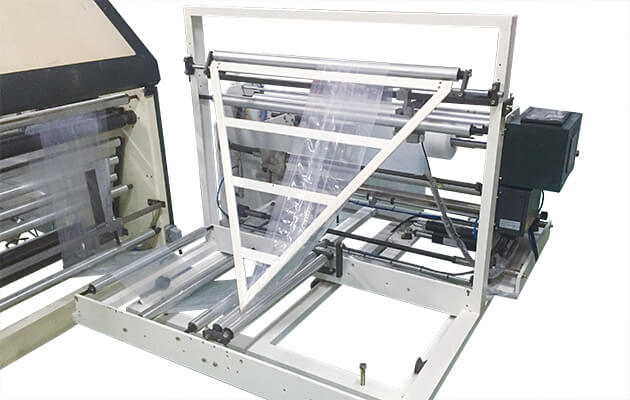

- Side seal system : Sealing and cutting done simultaneously and pull by rocking take out belt conveyor. Finished bag collected on table or conveyor.

- Synchronized Feeding and cutting speed : Inverter controlled feeding matching main machine speed for easy operation without manual adjustment.

- German "Sick" photocell registration : Reliable and accurate print registration and positioning

- Auxiliary air-blown outfeed : Air blown assists material flow of outfeeding

- LCD touch panel : Easily operable human-computer interface to access parameter changes and production monitoring /li>

- Socket type IC circuit control : Automated control system can be easily replaced by socket plugin.

- Malfunction alarm / stop : Alarm & auto-stops for abnormal temperature / No material feed / Photocell tracking miss (3 times)

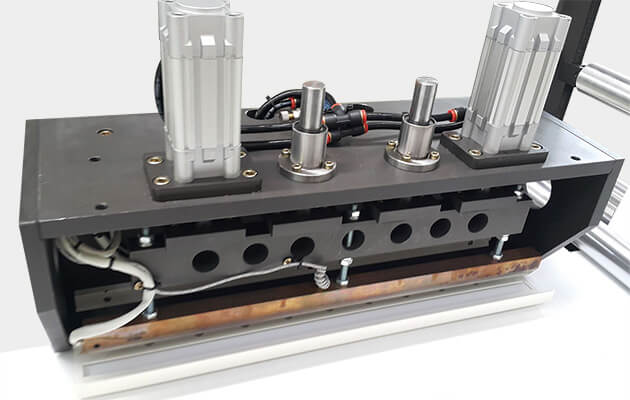

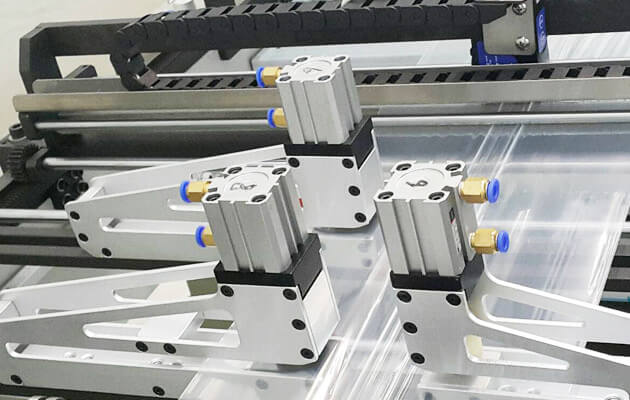

- Patch handle bag - Includes film feeding & cutting devices. Patch piece welded by heat press against the main body.

- Efficient Production - State-of-the-art shopping bag making machine featuring a unique side seal patch handle for synchronized sealing and cutting.

- User-Friendly - Equipped with an intuitive LCD touch panel and automated control system for smooth operation.

- Versatile & Reliable - Designed to handle various bag types and sizes, boosting productivity and quality.

Our shopping bag making machine utilizes cutting-edge technology and automated control systems to efficiently produce a variety of shopping bags. Whether it’s for everyday packaging or custom design requirements, our advanced production capabilities help clients enhance productivity and ensure high product quality.

Available Optional Device

Model

Choose the correct model specification

Explore from existing machines and find out endless opportunities