T-shirt bag making machine + bag folding system

BFDGFA-V

- Up-down die cut - Synchornized up-down die cut & feeding ensures stable & high speed performance. Vacuum waste film removal system for T-shirt bag on rolls.

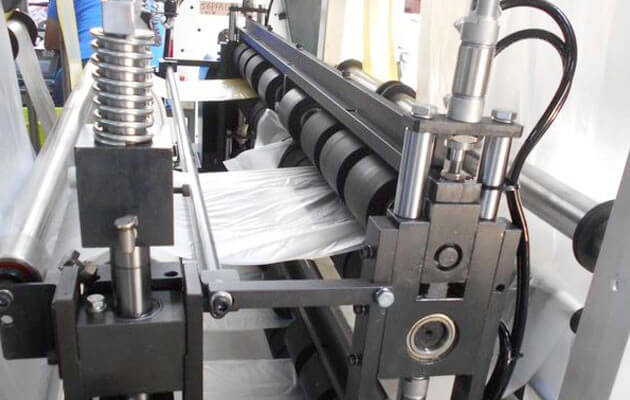

- Automatic Folding system - Servo-controlled 1st & 2nd fold individually (piece by piece), 3rd fold by pneumatic cyllinder every 1-15 pieces pile. 4th & 5th folds by optional.

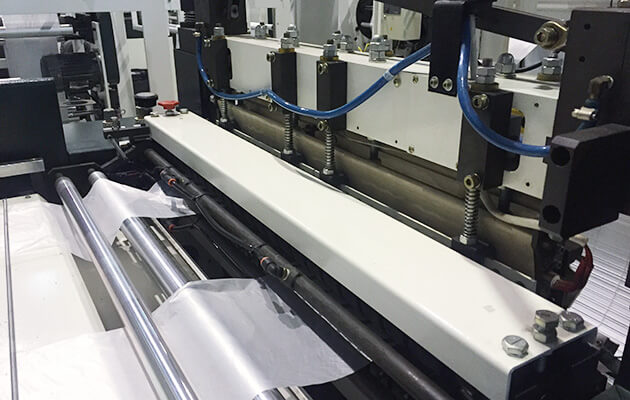

- Tensionless high speed hot-cut system : Upper sealing blade & bottom heating wire makes strong and high speed sealing. Tensionless sealing avoids sealing line pull& elongation for highspeed production. Seperated upper and bottom temperature control for easy micro-adjustment.

- Synchronized Feeding and cutting speed : Inverter controlled feeding matching main machine speed for easy operation without manual adjustment.

- German "Sick" photocell registration : Reliable and accurate print registration and positioning

- LCD touch panel : Easily operable human-computer interface to access parameter changes and production monitoring

- Socket type IC circuit control : Automated control system can be easily replaced by socket plugin.

- Malfunction alarm / stop : Alarm & auto-stops for abnormal temperature / No material feed / Photocell tracking miss (3 times)

Available Optional Device

Model

Choose the correct model specification

Explore from existing machines and find out endless opportunities