Plastic Bag Making Machines: Complete Guide to Bag Types, Materials, and Applications

In the evolving world of flexible packaging, plastic bag making machines are essential for efficiency, customization, and consistent quality. To help you stay competitive, this guide provides a complete overview of the industry's most high-demand sealing technologies, materials, machine options, and process flow required for modern production lines.

Bag Types and Their Corresponding Machines

Selecting the right plastic bag making machine begins with understanding how each bag type is technically defined. In modern converting operations, bag types are determined by sealing structure, compatible materials, production format, and functional modules.

While many specialized formats exist, bottom-seal and side-seal structures represent the vast majority of global plastic bag production. This classification follows the same engineering logic used by factories planning scalable, high-volume lines, focusing on these two primary sealing families to achieve maximum efficiency.

Sealing Structures: The Core of Machine Selection

Sealing structure is the most fundamental factor in choosing the correct machine family. It determines production speed, compatible films (HDPE, LDPE, OPP, CPP, laminates), seal strength, and the type of modules that can be added for specialized bag formats.

-

Bottom Seal Bags

Primary Machine: Bottom Seal Bag Making Machine

Best For: garbage bags, industrial liners, T-shirt bags, drawtape bags, bag-on-roll formatsWhy Bottom Seal Machines Dominate Heavy-Duty Applications:

- Strongest sealing strength for load-bearing products

- Handles thick / recycled films with high stability

- Suitable for high-speed continuous operations

- Supports 4–21 lane configurations for mass production

Common Bag Types:

- Standard garbage bags

- Drawstring garbage bags

- Industrial liners

- T-shirt bags (vest bags)

- Produce bags-on-roll

- Export jumbo rolls

(Bottom Seal Bag Making Machines) -

Side Seal Bags

Primary Machine: Side Seal Bag Making Machine Best For: e-commerce courier bags, OPP garment bags, stationery bags, clear retail packaging

Why Side Seal Machines Are Preferred for Retail Packaging:

- Superior clarity and seal appearance

- Extremely high cycle speed

- Ideal for OPP/CPP

- Seamless integration with hot-melt glue, zipper, and tear-strip modules

Common Bag Types:

- Courier/mailing bags

- OPP garment bags

- Stationery bags

- Retail display bags

- Side-seal zipper bags

(Side Seal Bag Making Machines)

Functional Modules: How Machines Produce Specialized Bag Types

Once the sealing structure is determined, factories use functional modules to create value-added or complex bag formats.

-

Drawtape Module

Installed on Bottom Seal Machines

- Tape folding, feeding, welding

- Perforation + film tension control

- Bag-on-roll rewinding

- Optional auto folding

Applications: Drawstring garbage bags, premium drawtape retail bags

-

Zipper & Slider Module

Installed on Bottom Seal or Side Seal Machines

- Inline zipper welding

- Slider insertion

- Track-and-hook sealing

- Optional zipper extrusion + blown film integration

Applications: food zipper bags, slider deli bags, grape bags

-

Bag-on-Roll Rewinder

Compatible with multiple machine families

- Core / coreless rewinding

- Perforation lines

- Tight, export-grade roll winding

Applications: garbage bags-on-roll, produce bags-on-roll

-

Rotary Die-Cutting Module

Installed on Specialized Bag Making Lines(such as handle cut-outs or ventilation holes)

- Pattern cutting

- Decorative or functional shapes

Machine Mapping: The Complete Engineering Overview

The following table summarizes the real-world mapping of how factories configure machines and modules for each bag type.

| Bag Type | Sealing Structure | Primary Machine | Required Modules / Options |

|---|---|---|---|

| Garbage bags | Bottom Seal | Bottom Seal Machine | Bag-on-Roll / drawtape / perforation |

| Drawtape bags | Bottom Seal | Bottom Seal + Drawtape Module | Rewinder / folding system |

| T-shirt bags | Bottom Seal | T-shirt Bag Machine | Punching / multi-line |

| Courier bags | Side Seal | Side Seal Machine | Hot-melt glue / tear strip |

| Zipper bags | Side Seal | Zipper Bag Machine | Inline zipper / slider / profile extrusion |

| Stationery bags | Side Seal | Side Seal Machine | Gusseting / punching |

| Produce bags | Bottom Seal | Bottom Seal Machine | Bag-on-Roll |

| Heavy-duty liners | Bottom Seal | Heavy-Gauge Bottom Seal | Heat-slitting |

Machine capability is only one part of production planning. The material you choose further determines sealing performance, production speed, and regulatory compliance.

Material Comparison: PE, PP, HDPE, and Biodegradable Options

Your choice of raw materials affects not only bag properties but also compliance with regulations and consumer expectations.

| Material | Properties | Typical Applications | Notes |

|---|---|---|---|

| LDPE | Flexible, clear, good sealing | Shopping bags, liners | Widely used, easy to process |

| HDPE | Strong, opaque, thinner film | T-shirt bags, garbage liners | Cost-effective, strong but less clear |

| PP | High clarity, heat resistant | Specialty pouches, food packaging | Premium look, higher sealing temp |

| Biodegradable (PLA, PBAT, starch blends) | Compostable, eco-friendly | Eco bags, regulated markets | Must meet standards (EN 13432, ASTM D6400) |

Machine Selection and Configuration Insights

Beyond selecting the right machine type, today’s plastic bag production benefits from automation and modular flexibility.Modern bag making systems allow manufacturers to balance efficiency and scalability.

- Fully automatic lines – Minimize labor while maintaining consistent sealing and cutting precision.

- Servo-driven systems – Enhance film control, reduce waste, and improve energy efficiency.

- Modular add-ons – Options such as inline printing, punching, gusseting, or zipper units enable customization and future upgrades.

Quick Decision Pointers:

- Define your target bag types and monthly production volume.

- Confirm that your machine supports your chosen film materials (PE, PP, biodegradable blends).

- Balance automation level with ROI expectations—avoid over-investing in capacity you won’t use.

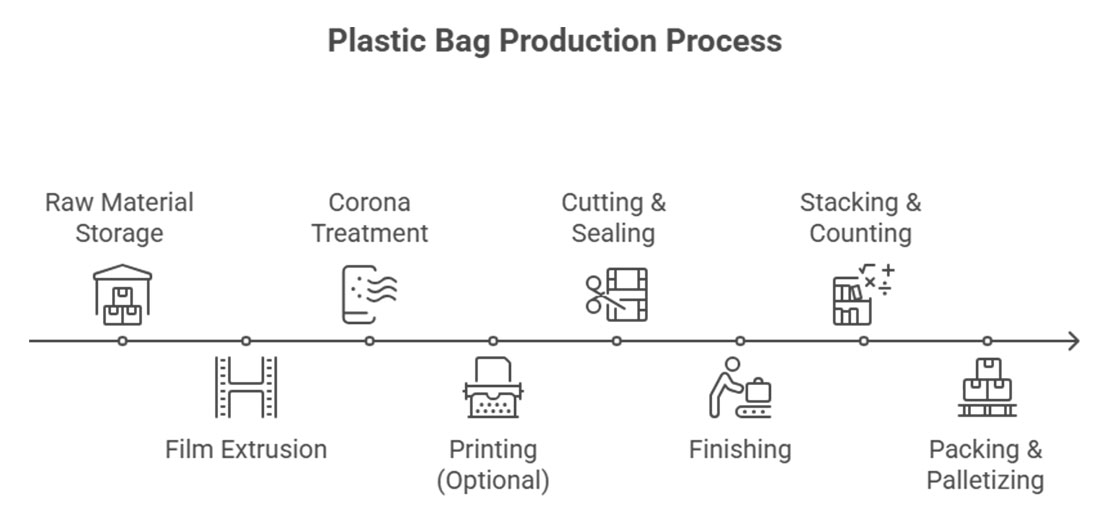

Step-by-Step Plastic Bag Manufacturing Process

A modern plastic bag making process involves several stages:

- Raw Material Storage – Resin pellets stored under controlled conditions.

- Film Extrusion – Plastic melted and blown into thin film rolls.

- Corona Treatment – Surface treatment for printing adhesion.

- Printing (Optional) – Flexographic or gravure printing on film.

- Cutting & Sealing – Film cut to size and sealed (bottom or side).

- Finishing – Gusseting, perforation, zipper, or punching.

- Stacking & Counting – Bags automatically stacked for packing.

- Packing & Palletizing – Final packaging for shipment.

This flow shows the journey from resin to finished bag.

Cost Considerations in Machine Investment

The price of a plastic bag making machine is not a single figure—it varies based on:

- Machine type and scale – compact semi-auto vs. high-speed full auto lines.

- Automation level – servo-driven systems and advanced controls reduce labor but raise initial investment.

- Optional modules – perforation, zipper insertion, inline printing, or drawtape systems.

- Energy efficiency – modern systems lower power use and film waste.

- After-sales service – training, spare parts, and maintenance support ensure long-term uptime.

Instead of focusing only on the purchase price, manufacturers should evaluate the total cost of ownership (TCO)—covering energy, waste, downtime, and service. A higher upfront investment often results in lower operating costs and faster ROI.

For ROI modeling and detailed buying frameworks, see our Buyer’s Guide: Choosing the Right Plastic Bag Making Machine for Your Needs.

Tailored Solutions with PLAS ALLIANCE

Choosing the right bag making machine is not just about speed—it’s about integration, flexibility, and long-term ROI. For example, PLAS ALLIANCE recently supported a Southeast Asian manufacturer in upgrading from semi-automatic to fully automatic bottom seal machines. The result was a 30% reduction in labor cost, faster delivery cycles, and compliance with new biodegradable film regulations.

With decades of engineering experience, PLAS ALLIANCE delivers more than just machines. We design complete production lines—integrating extrusion, printing, and bag making—to help clients improve efficiency, reduce costs, and meet sustainability goals.

Ready to take the next step? Sort by bag type to quickly find the right machine for your end-product and start planning your ideal production line today.

Date:2024-09-11

Date:2020-05-20

NEWS

NEWS