Buyer’s Guide: Choosing the Right Plastic Bag Making Machine for Your Needs

Choosing the right plastic bag making machine can be simple with a clear, six-step framework. This buyer’s guide aligns selection with your production goals, budget, and sustainability targets—plus the strategic, compliance, and financial planning needed to launch or scale a plant.

-

Define Your Production Needs and Scale

Before selecting any machine, start by identifying three essentials: what you plan to produce, your expected daily or monthly output, and the bag types that fit your target markets. For example, a startup producing around 50,000 T-shirt bags per month will value flexibility and lower setup costs. In contrast, a high-volume plant manufacturing 500,000 garbage bags or multi-layer pouches should focus on automation, production speed, and durability.

Once you have a clear estimate of your output, evaluate where you stand on the production scale. This will help you determine the appropriate machine capacity and prevent both overinvestment and underperformance. By defining your production scale early, you can ensure that your investment strategy supports future growth—before the machine is even installed.

Production Level Typical Monthly Output Target Products Key Priorities Recommended Machine Type Startup Around 50,000 T-shirt bags/month Retail & Grocery Bags Flexibility, lower setup cost Semi-Automatic Bottom Seal Machine with Basic Punching Options — Cost-effective setup with essential functions for flexible small-batch production. Mid-Size Factory Around 200,000 garbage bags/month Supermarkets & OEM Packaging Balance between speed and stability Automatic Bag Making Machine with Inline Auto Punch System — Supports inline punching to reduce manual handling and save labor costs. High-Volume Plant Over 500,000 pouches/month Industrial & Multi-layer Film Bags Automation, high-speed output, long-term durability High-Speed Multi-Line Fully Automatic System with Inline Auto Punch & Auto Packaging — Designed for high output efficiency with multi-line operation, integrated automatic punching, and automatic packaging.

Case Example:

A Southeast Asian manufacturer underestimated demand for perforated garbage bags and soon needed to upgrade to a higher-capacity plastic bag making machine with a 4-shaft rewinder system.

-

Understand Material Compatibility

Your machine must be compatible with the film materials you plan to use—whether conventional polyethylene (LDPE, HDPE, LLDPE), recycled blends, or biodegradable films. Each material requires specific tension control, sealing temperatures, and feeding systems.

Tip: If you want to dive deeper into material properties and comparison, see our Complete Guide to Bag Types and Materials.

-

Evaluate Automation and Control Systems

Automation is essential if you want to reduce labor and improve consistency.

- Semi-automatic machines are more affordable but require operators for tasks like loading rolls or removing finished bags.

- Fully automatic lines integrate servo control, touchscreen interfaces, and advanced monitoring—delivering faster production and fewer errors.

Case Example:

A North American converter upgraded to a servo-driven system and improved production speed by 30% while reducing film waste by 15%. This investment only paid off because their production volume justified the automation cost.

-

Assess Optional Features and Add-Ons

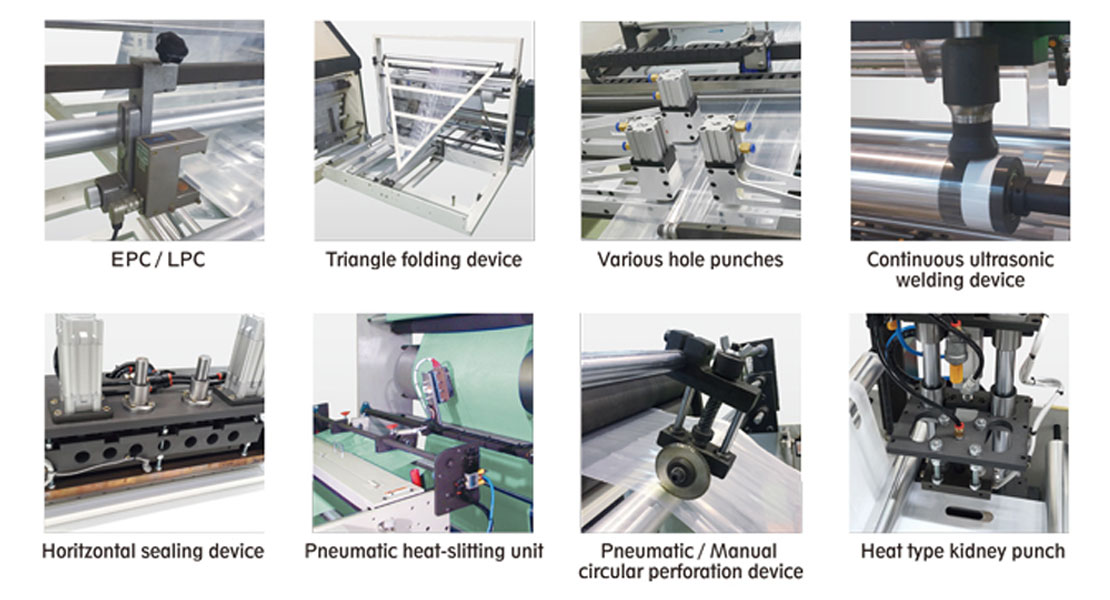

From inline printing to perforation units and gusset folders, optional modules can make your line more versatile. For example, a producer of courier envelopes invested in a side-seal machine with integrated hot glue systems to create peel-and-seal strips—opening new markets.

-

Plan for Maintenance, Support, and Spare Parts

Even highly automated lines rely on disciplined maintenance to sustain uptime. No matter how sophisticated your bag making machine is, downtime is costly. Choose suppliers offering local technical support, readily available spare parts, and comprehensive training. Preventive maintenance plans can help avoid unexpected breakdowns and keep production on schedule.

-

Calculate Total Cost of Ownership

Total cost of ownership goes beyond the purchase price—it also covers installation, training, spare parts, energy consumption, labor, and maintenance.

Factor Low-Cost Machine High-Quality Machine Initial Price Lower Higher Energy Use Higher Optimized Waste Rate 8–10% 2–3% Downtime Frequent Rare ROI (5 yrs) Negative Positive For a broader perspective on factory-level investment and ROI modeling, see our article How to Start a Plastic Bag Making Machine Plant: A Practical Guide to Setup & ROI.

Final Buying Tips for Plastic Bag Making Machines

Choosing the right plastic bag making machine sets the foundation for efficiency, product quality, and long-term ROI. By defining production needs, ensuring material compatibility, and balancing automation with cost, manufacturers can scale confidently in today’s competitive packaging market.

Frequently Asked Questions (FAQ)

Before exploring tailored solutions, here are answers to some of the most common buyer questions:

Q1: What is the difference between side seal and bottom seal machines?

Side seal machines create seals along the sides, ideal for courier bags and resealable pouches. Bottom seal machines produce stronger seals at the bottom, better for heavy loads and garbage bags.

Q2: Can one machine produce multiple bag types?

Yes, but you may need optional modules (e.g., zipper units, perforation stations) to handle various formats.

Q3: How long does installation and training take?

It typically ranges from a few days to several weeks, depending on machine complexity and operator experience.

Q4: Do all machines support biodegradable film?

Not all. You must confirm compatibility before purchase.

Tailored Solutions with PLAS ALLIANCE

With these fundamentals in mind, it’s time to explore how different machine types align with specific applications:

-

Retail & Consumer Packaging

– T-Shirt Bag Machines, Zipper Bag Machines, Pouch Bag Machines -

Industrial & Heavy-Duty Use

– Drawtape Garbage Bag Machines, Bag On Roll Machines, Bottom Seal Machines -

Specialized Applications

– Side Seal Machines, Flower Sleeves Machines, Auxiliary Equipment

These solutions demonstrate how PLAS ALLIANCE supports diverse needs—from high-volume retail bags to niche floral sleeves. Whether you’re scaling up or just getting started, our team can configure an optimized production setup.

Contact PLAS ALLIANCE today for expert consultation and tailored recommendations.

Date:2024-09-11

Date:2020-05-20

NEWS

NEWS